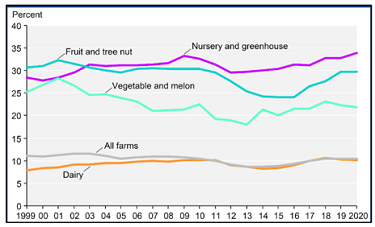

There is widespread recognition that the cost and availability of labor form one of the leading challenges for U.S. specialty crop growers (e.g., Calvin, Martin, and Simnitt, 2022; IFPA, 2023; USDA-ERS, 2023; Martin, 2024). On average, labor expenses account for 12% of total gross cash farm income across all U.S. farms (USDA-ERS, 2023). While this average share has changed very little over time, even as total costs have increased, the labor landscape looks very different for most specialty crops. From 2003 to 2020, nursery and greenhouse industries spent the largest portion of their total gross cash farm income on labor, averaging 34% (Figure 1). The fruit and tree nut industries followed closely behind at about 30% of gross income. Differences among individual specialty crops are even more notable. For example, labor expenses expressed as a percentage of gross income are estimated to be as high as 50% for almonds and 60% for table olives (Niederholzer, Ott, and Jarvis-Shean, 2024; Cicek, 2011).

Mechanized solutions such as precision agriculture, remote sensing, mechanical harvesters, and labor-aids offer potential benefits as labor-saving technologies. Yet the adoption of such technologies has been uneven, over time and across commodities (Gallardo and Sauer, 2018). Rogers’ (1962) classical depiction of innovation adoption includes five stages:

In the end, Rogers concluded that just five factors drive (or oppose) adoption:

This article examines why growers might adopt mechanization through an investment, or relative advantage, perspective.

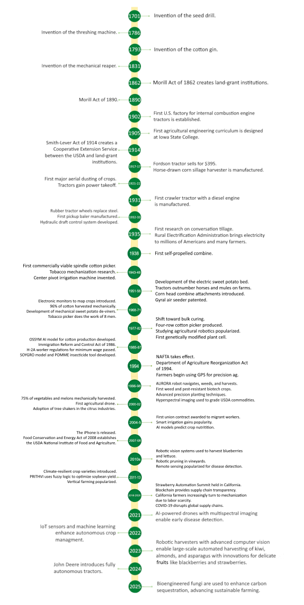

An obvious first step (not mentioned by Rogers) in substituting mechanization for labor in specialty crops is that the technologies must exist and be available for commercialization. Concerns over labor availability and affordability are not new, and neither are attempts to develop mechanization. For example, the seed drill, threshing machine, handheld seed tube, and cotton gin predate the 1800s, and the first factory for internal combustion tractors was established in 1902 (Figure 2). Technology solutions designed for specialty crops did not emerge as early, but several crops (typically serving processed product markets) transitioned to mechanical harvesting solutions. Harvesting for processing tomatoes was largely mechanized by 1970 (Schmitz and Seckler, 1970) and mechanical harvesting for tart cherries was pervasive by the early 1970s (Wright, Martinez, and Thornsbury, 2006; Ricks, Hamm, and Chase-Lansdale, 1982). In the 1970s, mechanical harvesting also emerged for processing olives, juice grapes, some wine grapes, carrots, almonds, and pistachios (Hendrickson and Oberholster, 2017; Sarig, 2012).

The specialty crop sector comprises hundreds of unique crops and growing situations, with the emergence of new or differentiated crops ongoing. While this creates opportunities for market development and response to consumers, it can create challenges for the commercialization of innovative technologies. Agricultural research and manufacturing interests are more likely to focus on the needs of the almost 300,000 U.S. farms (80.6 million acres) growing corn for grain in 2022 than the needs of the less than 8,500 U.S. farms (73,500 acres) growing strawberries or even the 27,500 farms (411,000 acres) growing apples. Technology development for specialty crops must either target a relatively small number of potential users or be adaptable over differentiated use cases. As they mature, additive manufacturing technologies could eventually expand solutions for small-volume agricultural needs as they have in manufacturing sectors of the economy (Lu et al., 2024).

Even accounting for small volumes, the high value of most specialty crops may provide opportunities for investment in mechanization. In Florida alone, the nursery and greenhouse industries generated $3.98 billion in total sales in 2022 with labor expenses totaling 34% of farm income (Khachatryan et al., 2023); fruit industries generated $1.29 billion in revenue and vegetable and melon industries added an additional $1.31 billion in revenue in 2020 (FDACS, 2024).

Understanding the potential benefits and need for modern agricultural tools, the U.S. Department of Agriculture (USDA) has invested in the development of mechanized and automated solutions for specialty crop industries. Astill, Perez, and Thornsbury (2020) identified six programs across four USDA agencies that had made investments totaling $287.7 million (nominal) in 213 projects with a focus on automation or mechanization for specialty crops between 2008 and 2018. Each of these programs was designed differently to achieve unique objectives, with specialty crop automation or mechanization projects as a subcomponent. While substantial in value, these investments accounted for only 3% or less of the total funds allocated by the programs. An additional three programs in USDA Rural Development (RD) were identified that funded $3.4billion from 2010 to 2018 to support the digital infrastructure needed for adoption of automation ormechanization. More recent policies may impact incentives for mechanization or technology development including policies proposed to improve working conditions, expand legal pathways for migrant workers, and disaster relief programs (USDA-FSA, 2022). In 2024, the USDA announced a $2 billion investment to help specialty crop growers overcome market barriers and expand crop storage (USDA, 2024).

Industry associations are also investing in technological solutions. For example, the California Strawberry Commission funds an initiative to develop and test mechanical harvesters, particularly in fields with varying terrain and foliage density (Yeh et al., 2023). Their investments in innovating robotic technologies and automated harvesting systems demonstrate how pivotal some believe these technologies will be in assuring the strawberry sector’s long-term future.

More recently, there has been growing interest from sectors that have not traditionally focused on agriculture. Investment from both private equity and venture capital firms has grown over time (Brady, 2023). Total agricultural investments from venture capital markets did decline in 2022 (largely driven by market shakeouts in eGrocery and alternative protein spaces), but continued to increase in ag biotech, bioenergy and biomaterials, farm management software and internet of things (IoT), and novel farming systems (AgFunder, 2023).

Moving technologies from development to commercialization has not been easy. It is useful to consider innovation for specialty crops through the lens of technology readiness levels (TRLs), a standardized metric used to assess the maturity level of a particular technology as it moves through development to widespread use (Mankins, 1995; Tomaschek et al., 2016). TRL stages 1–4 correspond to the precompetitive space, where research primarily focuses on basic or foundational science and is often exploratory and driven by a big-picture, long-term need. In TRL stages 5–8, the focus is advancing revolutionary technologies that need further refinement before commercialization; for instance, adjustments to specific end-uses. In the final stages (TRL 8–9), technologies that have been created and fine-tuned undergo a process of technology transfer and deployment.

The innovation “valley of death” occurs when a technology has reached proof of concept (meaning it works in a controlled setting) but still requires significant development to operate in real life (Gbadegesjn et al., 2022). Typically, this demise happens when an innovation fails to progress from TRL 4 to TRL 7. Although the field of agricultural technology continues to expand (Mickolio, 2024), many applications are lingering in the valley of death. Challenges such as data standardization, interoperability, and rural broadband connectivity are often significant barriers to mass adoption.

Heterogeneity, not just between different specialty crops and growing systems but within the individual crops and plants themselves (e.g., apples are not located in exactly the same places on every tree), creates significant challenges to operable solutions, particularly for fresh produce. These logistical challenges can slow the rate of technological development. For example, despite high labor costs and multiple technologies in various stages of development, strawberry harvesting is still mostly performed by hand (Yeh et al., 2023). Strawberries are delicate and highly perishable, so harvesting tools developed for processed products cannot be readily adapted without causing significant damage. During harvest, fruit clustering is a significant challenge for mechanical strawberry harvesters, and solutions to separate clusters of ripe and unripe berries in a consistent fashion have not been perfected (Zhou et al., 2022). Bruised fruit is also more susceptible to pests and pathogens, creating additional quality problems in the supply chain (Hussein, Fawole, and Opara, 2020). Crops that require multiple harvests, either within or across seasons, face additional challenges from damage to the plant (or tree) itself (Charlton et al., 2019). Unique needs among the myriad commodities, markets, and supply chains comprising specialty crops make common solutions challenging.

Mechanization in agriculture represents a critical tipping point where the balance between labor-intensive practices and automated solutions shifts decisively toward (or away from) technology. Just because technology exists does not mean an individual firm will be incentivized to adopt it. There is increasing economic pressure to find solutions, as farm labor is likely to continue to become less available and more expensive in the future (USDA-ERS, 2023).

According to a survey by the California Farm Bureau, over 40% of farmers have faced challenges in securing sufficient labor for their main crops in recent years (Daniels, 2019). Factors identified as exacerbating shortages include stricter immigration policies and an aging immigrant farmworker population. In New Jersey’s nursery crop operations, Gohil, Waller, and Cabrera (2022) found that despite challenges in mechanizing tasks like pruning due to the diversity in plant sizes and shapes, there was growing recognition of the need for greater mechanization to enhance operational efficiency.

Still, individual adoption of new technologies and diffusion of those technologies across communities is complicated, and the pace of change is intense, requiring integration of assets from disparate sources for the successful delivery of solutions. Low margins and agronomic challenges can shift interest and attention toward the short- and medium-term survival of the farm operation, decreasing the operator’s ability and interest to invest in new technologies.

Affordability and scalability of technologies are prime examples of relative advantages, as conceptualized by Rogers (1962), that drive on-farm adoption. Existing mechanized harvesting solutions (e.g., robotic picking and vision systems) are expensive and vary widely in cost. Large-scale operations often find mechanization to be more feasible, as fixed costs can be spread over a larger production volume. For citrus harvesting, the cost of such technology starts at $80,000 for robotic materials and several hundred thousand dollars for a vision system, not counting maintenance expenses (Yeh et al., 2023). Adjusting the technology to specific crops and situations can be challenging; any damage to vulnerable plants and fruit will add to costs (Moran, 2016).

While labor costs and availability heavily influence the decision to mechanize, comparing manual labor costs and the capital investment required for mechanized equipment is only a first, and insufficient, step in the decision process. The partial budgeting approach often applied to measure the feasibility of a new technology does not provide relevant information in and of itself. Data limitations typically constrain this type of analysis to an aggregated level or a representative farm. Thus, by definition, the results will not reflect the situation for individual decision making. At a minimum, scenario analysis projections could account for a range of potential adopters across farm size and type. Unlike technologies with widespread markets (e.g., iPhones), the cost of technologies with a limited market is not likely to decrease over time. A realistic assessment of market size for a new technology that includes purchase and maintenance costs can provide insights into the likelihood of the technology’s eventual commercialization. Risk analysis for individual firms is critical.

Often, technology adoption is not just a trade-off between the initial investment and annual operating costs. Instead, it also involves significant system redesign, including how labor is integrated into the resulting new system. For example, in a 2015 survey of apple operations in Washington, Gallardo and Brady (2015) found that only 11% of apple operations were using platforms, even though that relatively low-tech labor aid had been available on the market since the 1990s. The primary reason cited for nonadoption was the technology’s incompatibility with the existing orchard design. Adoption continued to lag even as producers transitioned to high-density trellis planting which would physically accommodate platforms. While platforms reduce the number of workers needed, workers are constrained to pick apples at roughly the same pace (i.e., accommodating the speed of the slowest picker).

Additional difficulties arise for perennial crops. Wright et al. (2006) demonstrated that the ability to adopt new mechanical harvesting technologies for tart cherries was not only dependent on the relationship between improved yields and the investment in new technology. Adoption was also critically dependent on the time that the grower needed to recuperate sunk cost investments in required redesign of the orchard. These transition periods and lags were critical factors increasing the reluctance to adopt new systems.

Every farm and location site are unique, and not every technological solution is a fit. For example, slow-moving conveyor belts have been used in Oxnard, California, as a labor aid to assist pickers in the strawberry industry. However, conveyor belts are far less useful in the hillier terrain and smaller fields found in the Salinas-Watsonville area of California (Calvin, Martin, and Simnitt, 2022).

Progress from development to deployment towidespread use of some new technologies emerging inagriculture continues to face obstacles. There are no quick fixes when building new attitudes, skills, and systems. A seminal article by Holt (1989) highlighted the importance of going beyond explaining new researchfindings and touting new technology to actively engage with people within the context of their production and marketing systems. Economists can help by including information on strategic investments based on potential for adoption, payoffs, or future supply shortages.

Labor shortages have compelled U.S. specialty crop growers to explore mechanization as a potential path to lower costs. On-farm labor-saving technologies are rapidly evolving, with innovations such as precision farming, autonomous tractors, and robotic harvest aids that can create a foundational platform and raise the probability of finding application solutions. Opportunities to integrate artificial intelligence and machine learning in agricultural production and marketing tools promise to further revolutionize farming practices.

Ultimately, transitions will be driven by individual decisions to adopt new technologies. Each operation must evaluate productivity and profitability while fitting the new technology within the context of its production system, overall financial situation, risk profile, and global supply chains. A simple evaluation of relative advantage based on partial, or enterprise, budgets will not serve as a good indicator of adoption feasibility. As technologies continue to advance and regulatory landscapes evolve, the future of agriculture hinges on fostering innovation that not only enhances but also fits into farmers’ daily lives.

By recognizing system-wide implications and asking the hard questions, economists can help stakeholders navigate the hurdles of technological adoption more strategically. Farms must survive within the context of their supply chains and the competition of the global marketplace. Ultimately, relative advantage as measured by partial budgeting does not address firm (or industry) competitiveness. A firm can decrease total costs and still not be competitive. As industry continues to witness rapid advancements in agricultural technologies, understanding these dynamics will be crucial in shaping the future of the global food system.

AgFunder (2023). “Global AgriFood Tech Investment Report” https://agfunder.com/research/agfunder-global-agrifoodtech-investment-report-2023/

Astill, G., A. Perez, and S. Thornsbury. 2020. Developing Automation and Mechanization for Specialty Crops: A Review of U.S. Department of Agriculture Programs: A Report to Congress. USDA Economic Research Service Administration Publication AP-082.

Brady, M. 2023. “Private Equity’s Role in Transforming Agriculture.” Vision Magazine. Available at: https://www.visionmagazineus.com/private-equitys-role-in-transforming-agriculture/ [Accessed September 28, 2024]

Calvin, L., P. Martin, and S. Simnitt. 2022. “Adjusting to Higher Labor Costs in Selected U.S. Fresh Fruit and Vegetable Industries.” USDA Economic Research Service Economic Information Bulletin EIB-235.

Charlton, D., J.E. Taylor, S. Vougioukas, and Z. Routledge. 2019. “Innovations for a Shrinking Agriculture.” Choices 32(2).

Cicek, G. 2011. “Determination of Harvesting Costs and Cost Analysis for Different Olive Harvesting Methods.” Journal of Food, Agriculture, and Environment 9(3&4):201–204.

Daley, L. 2023, July 20. “Technology Readiness Levels – What Are They and Why Are They Important?” In-Part. Available online: https://in-part.com/blog/technology-readiness-level-what-is-it-and-why-is-it-important/ [Accessed September 28, 2024]

Daniels, J. 2019, May 1. “California Farmers Increasingly Turning to Mechanization Due to Labor Shortages, Says Survey.” CNBC. Available online: https://www.cnbc.com/2019/05/01/farmers-turning-to-mechanization-due-to-labor-shortages-says-survey.html [Accessed August 19, 2024]

Florida Department of Agriculture and Consumer Services (FDACS). 2024. “Florida Agriculture Overview and Statistics.” FDACS. Available online: https://www.fdacs.gov/Agriculture-Industry/Florida-Agriculture-Overview-and-Statistics [Accessed August 19, 2024]

Gallardo, R.K., and M. P. Brady. 2015. “Adoption of Labor-Enhancing Technologies by Specialty Crop Producers.” Agricultural Finance Review 75(4):514–532.

Gallardo, R. K., & Sauer, J. (2018). Adoption of labor-saving technologies in agriculture. Annual Review of Resource Economics, 10(1), 185–206. https://doi.org/10.1146/annurev-resource-100517-023018

Gbadegeshin, S.A., AA. Natsheh, K. Ghafel, O. Mohammed, A. Koskela, A. Rimpilainen, J. Tikkanen, and A. Kuoppala. 2022. “Overcoming the Valley of Death: A New Model for High Technology Startups.” Sustainable Futures 4:100077.

Gohil, H., T. Waller, and R. Cabrera. 2022. “Understanding Current Labor Shortage and Mechanization in New Jersey Nursery Crop Operations.” Journal of Extension 60(4).

He, L., and D. Weber. 2022. “Harvest-Assist Platforms for Apple Growers.” PennState Extension. Available online: https://extension.psu.edu/harvest-assist-platforms-for-apple-growers [Accessed September 28, 2024]

Hendrickson, D.A., and A. Oberholster. 2017. “Review of the Impact of Mechanical Harvesting and Optical Berry Sorting on Grape and Wine Composition.” Catalyst 1:21–26.

Her, Y.G., K.J. Boote, K.W. Migliaccio, C. Fraisse, D. Letson, O. Mbuya, A. Anandhi, H. Chi, L. Ngatia, and S. Asseng. 2017. “Climate Change Impacts and Adaptation in Florida’s Agriculture.” In E.P. Chassignet, J.W. Jones, V. Misra, and J. Obeysekera, eds. Florida's Climate: Changes, Variations, & Impacts. Gainesville, FL: Florida Climate Institute, pp. 235–267.

Holt, J. 1989. “Managing Change in Extension.” American Journal of Agricultural Economics 71(4):869–873.

Hussein, Z., O.A. Fawole, and U.L. Opara. 2020. “Harvest and Postharvest Factors Affecting Bruise Damage of Fresh Fruits.” Horticultural Plant Journal 6(1):1–13.

International Fresh Produce Association (IFPA). 2023. Future Trends Report. Available online: https://www.freshproduce.com/resources/consumer-trends/2023-future-trends-report/

Khachatryan, H., M. Knuth, A. Hodges, and C. Hall. 2022. Florida Nursery and Landscape Industry Economic Contributions Report. Food and Resource Economics Department, UF/IFAS Extension Publication FE1114.

Lu, Y., W. Xu, J. Leng, X. Liu, H. Xu, H. Ding, J. Zhou, and L. Cui. 2024. “Review and Research Prospects on Additive Manufacturing Technology for Agricultural Manufacturing.” Agriculture 14(8):1207.

Mankins, J.C. 1995. “Technology Readiness Levels.” NASA Office of Space Access and Technology, Advanced Concepts Office. Available online: https://aiaa.kavi.com/apps/group_public/download.php/2212/TRLs_MankinsPaper_1995.pdf [Accessed September 28, 2024].

Martin, P. 2024. Bracero 2.0: Mexican Workers in North American Agriculture. Oxford University Press.

Mickolio, J. 2024, May 20. “AgTech Advancements Powering Farming Innovations.” Global AgTech. Available at: https://www.globalagtechinitiative.com/digital-farming/agtech-advancements-powering-farming-innovations/ [Accessed August 19, 2024].

Moran, N. 2016, March 21. “Harvest More Profits.” Produce Grower. Available online: https://www.producegrower.com/article/harvest-more-profits/ [Accessed August 19, 2024].

Niederholzer, F., J. Ott, K.S. Jarvis-Shean, B. Wheeler-Dykes, C. Pierce, S. Gyawaly and B. Goodrich. 2024. “Sample Costs to Establish an Orchard and Produce Almonds.” University of California Agriculture and Natural Resources Cooperative Extension. Available online: https://coststudyfiles.ucdavis.edu/2024/07/09/2024SacValleyAlmonds7.5.24.%20Final%20draft.pdf [Accessed September 28, 2024].

Olechowski, A., L. Steven, D. Eppinger, N. Joglekar, and K. Tomaschek. 2019. “Technology Readiness Levels: Shortcomings and Improvement Opportunities.” Systems Engineering (23):395-408.

Ricks, D.J., L.G. Hamm, and W.C. Chase-Lansdale. 1982. The Tart Cherry Subsector of U.S. Agriculture: A Review of Organization and Performance. Studies of the Organization and Control of the U.S. Food System, N.C. Project 117, Monograph, 12.

Rogers, E.M. 1962. Diffusion of Innovations. New York: Free Press of Glencoe.

Sarig, Y. 2012. “Mechanical Harvesting of Fruit – Past Achievements, Current Status and Future Prospects.” Acta Horticulturae 965:163–169.

Schmitz, A., and D. Seckler. 1970. “Mechanized Agriculture and Social Welfare.” American Journal of Agriculture Economics 52:569–577.

Tomascheck, K., A. Olechowski, S. Eppinger, and N. Joglekar. 2016. “A Survey of Technology Readiness Level Users.” INCOSE International Symposium 26(1):2101–2117.

U.S. Department of Agriculture. 2024. “USDA Announces More Than $2 Billion to Strengthen Specialty Crops Sector, Expand Crop Storage for Producers Following 2024 Natural Disasters.” Available online: https://www.usda.gov/media/press-releases/2024/11/19/usda-announces-more-2-billion-strengthen-specialty-crops-sector [Accessed December 2, 2024].

U.S. Department of Agriculture, Economic Research Service (USDA-ERS). 2023. “Farm Labor.” Available online: https://www.ers.usda.gov/topics/farm-economy/farm-labor/ [Accessed August 19, 2024].

U.S. Department of Agriculture, Farm Service Agency (USDA-FSA). 2022. “USDA Seeks Input on New Grant Program to Strengthen Food Supply Chain, Reduce Irregular Migration, and Improve Labor Protections for Farmworkers.” Available online: https://www.fsa.usda.gov/news-events/news/09-21-2022/usda-seeks-input-new-grant-program-strengthen-food-supply-chain-14 [Accessed December 2, 2024].

U.S. Department of Energy. 2021. Improved Performance Planning Could Strengthen Technology Transfer. U.S. Government Accountability Office GAO-21-202.

Wright, R.T., L. Martinez, and S. Thornsbury. 2006. “Technological Leapfrogging as a Source of Competitive Advantage.” Paper presented at the SAEA annual meeting, Orlando, FL February 4–8.

Wu, F., Z. Guan, and M. Garcia-Nazariega. 2018. “Comparison of Labor Costs between Florida and Mexican Strawberry Industries.” Food and Resource Economics Department, UF/IFAS Extension Publication FE1023. Available online: https://edis.ifas.ufl.edu/publication/FE1023 [Accessed August 19, 2024].

Yeh, D.A., Kramer, J., Calvin, L., & Weber, C. (2023). The changing landscape of U.S. strawberry and blueberry markets: Production, trade, and challenges from 2000 to 2022 (Report No. EIB257). U.S. Department of Agriculture, Economic Research Service.

Zhou, H., X. Wang, W. Au, H. Kang, and C. Chen. 2022. “Intelligent Robots for Fruit Harvesting: Recent Developments and Future Challenges.” Precision Agriculture 23: 1856–1907.