In December 2014, highly pathogenic avian influenza (HPAI) was discovered in U.S. poultry, eventually affecting more than 48 million birds by July 2015. The outbreak heavily affected Midwest poultry, specifically Iowa and Minnesota. The majority of affected operations were turkey operations but the vast majority of affected birds were layer hens (67%), or chickens that lay eggs to be consumed as either table eggs or further processed egg products (USDA-APHIS, 2015). During the outbreak, animal health officials used a permitting process to aid in business continuity and to alleviate some of the physical and economic stress of the outbreak. These permits allowed movement of products and animals on and off non-infected premises that were located within control areas, typically a ten-kilometer radius area surrounding infected premises, reducing potential costs associated with the outbreak.

Business continuity planning provides a way for the various stakeholders, such as producers, industry, and government, to prepare for unplanned events that could negatively impact business operations (Zsidisin, Melnyk, and Ragatz, 2005). This pre-planning provides guidelines on how to reduce business disruptions during an animal disease outbreak (Hennessey et al., 2010), especially when the disease management strategies are considered economic “wicked problems”, or those that are difficult to solve for various, contradictory reasons (Miller and Parent, 2012). Plans must account for risk of disease spread, disease exposure rates, and unintended consequences of allowing movement within and outside control areas. These unintended consequences are those effects that are not intended with the disease management strategy including spread of disease to a non-infected premise that increases the cost and longevity of an outbreak. If the risks associated with movement were such that the benefits of movement outweigh potential unintended consequences, then product movement could occur.

For the egg layer industry, these unintended consequences could affect multiple groups along the supply chain. First, contract and independent producers could be affected through losses in income and additional costs of egg and egg product disposal that are prohibited from moving outside the control area. Second, processors and integrators could be impacted through processing disruptions and retail shortages. Third, due to an egg shortage, consumers could be affected through higher price for eggs and egg products. Finally, government stakeholders, at all levels, could be affected through the cost of indemnity and disease control as well as eradication measures. Planning and developing management strategies for disease outbreaks can potentially alleviate some of these business strains as evidenced by the recent outbreak of HPAI in the U.S. poultry industry.

Business continuity planning for the U.S. egg industry began in 2006 when personnel at the U.S. Department of Agriculture's Animal and Plant Health Inspection Service’s (USDA-APHIS) along with other federal and state agencies, academia, and industry formed the Egg Sector Working Group to assess the risk of spread of HPAI associated with movement of various poultry products. Issues identified by the Egg Sector Working Group are addressed through a series of proactive risk assessments for poultry products which analyze the disease spread risk of movement of products and farm inputs within and from outside of a control area. This working group was instrumental in developing the Secure Egg Supply plans to help support business continuity in the egg industry (Hennessey et al., 2010). These proactive risk assessments are useful in preparing and planning for a permitting process in the event of an outbreak to be readily applied, as opposed to reactive risk assessments being estimated after an outbreak occurs slowing down the permitting process.

The risk assessments follow the World Organization for Animal Health (OIE) standards and guidelines that were introduced to address the Agreement on Sanitary and Phytosanitary Measures by the World Trade Organization (OIE, 2013a; 2013b). These risk assessments include an entry assessment, exposure assessment, consequence assessment, and risk estimation. Entry and exposure assessments estimate the disease spread risks associated with product movement inside and outside of control areas, and have been completed for seven egg commodities (USDA-APHIS, 2013). The seven egg commodities include: pasteurized liquid eggs, non-pasteurized liquid eggs, washed and sanitized shell eggs, nest run shell eggs, hatching eggs, day-old chicks, and egg shells and inedible eggs.

With any highly infectious disease outbreak, there is the potential risk of increased disease exposure by allowing movement from the control area. The movement of shell eggs from monitored premises have been assessed to pose relatively low additional risk for disease spread over a baseline scenario of movement restrictions, where movement is not allowed within the control area (USDA-APHIS, 2010). However, any potential increase in the spread of disease could result in increased depopulation and disposal costs, other direct costs to producers, a reduced supply of sellable eggs and increase in retail prices, increased indemnity payments by the government, and restocking costs once this is allowed. Consequence assessments should account for these decisions made during an outbreak, and the proactive risk assessments address these management decisions, which are then incorporated into the economic consequences.

To date, the entry and exposure risk assessments have focused on evaluating the likelihood of susceptible poultry becoming exposed via movement of poultry products. These assessments are publicly available as the Secure Egg Supply Plans (USDA-APHIS, 2013). These assessments’ disease management recommendations were incorporated in the decision making process by state and federal agencies when managing the most recent HPAI outbreak, providing a framework for disease management strategies. The final step for risk assessment is the risk estimation, which will integrate the results from the entry, exposure, and consequence assessments.

The consequence assessment, or a benefit-cost analysis, for business continuity is being developed. To assess the benefits and costs of allowing movement of products and farm inputs during a HPAI outbreak, animal health officials need to consider multiple decision factors including:

This economic portion of the consequence assessment will be incorporated with the entry and exposure assessments to provide a final risk estimate for business continuity.

To manage the spread of a disease, pre-defined control areas are established around infected, detected premises. The control area is defined as the area in which disease management protocols dictate movement within and outside for a specified radius, commonly 10-15 kilometers (USDA-APHIS, 2015b). These control areas almost always include non-infected premises as well. Non-infected premises within the control area are at the center of business continuity discussions, as these premises under stop movement orders are prohibited from moving products on or off farm during a disease outbreak due to geographic location. Products requiring movement permits include egg products produced on farm as well as feed and farm inputs moving onto these premises from outside the control area.

According to the Secure Egg Supply Plans, premises that increase their biosecurity measures to include key points of protection such as truck washing for movement both onto and off of premises, personal protective equipment used by farm workers that are site specific, proper disposal of waste and euthanized birds, and disease monitoring can apply for movement permits. These permits require premises to test negative for HPAI prior to any movement, with continued testing to ensure a disease free premises. For example, nest run shell eggs must have two negative avian influenza polymerase chain reaction (PCR) pools per house and a holding period of two days, or a period when products are stored until allowed to move, where one of the samples must be taken on or after the second day (USDA-APHIS, 2013). When these requirements are met, premises may request movement permits that sanction selected movements.

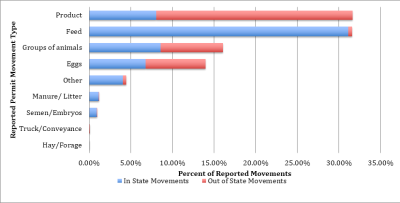

Source: USDA-EMRS, 2016

All permits must go through state animal health agencies. The typical process for permits is to submit a request, review of the request, approval or denial of the request, and finally movement. The request could be for single or multiple movements for a specified period of time. All permits must be recorded by the state agencies and should be approved by the receiving state for both interstate and intrastate movements. The majority of states use USDA’s Emergency Management Response System (EMRS) for data entry and those that do not, eventually recorded their permits into this central system. All steps should be recorded in EMRS accurately and in a timely manner. All permits are reviewed, and if movement stipulations are not consistently met, permits may be revoked.

During the 2015 U.S. HPAI outbreak, approximately 7,800 permits were awarded accounting for approximately 20,000 movements as reported in EMRS in April 2016. These permits were issued for individual and multiple intra and interstate movements. Not all movements were consistently recorded in EMRS. The reported permits mainly included movement of feed, farm products, and live animals as shown in Figure 1. It should be noted that semen/embryo movement is considered high risk for potential disease spread. Currently, there are no permitting guidelines for secure movement. All movements of any products are at the discretion of state health officials. Of the permitted movements reported, 61% of all movements were in-state movements. The proportion of movements varies with the individual item type. For example 98% of all feed movements originated in the same state as the destination premises. Non-essential movements were restricted during the outbreak. However, with the permitting process, essential movements were allowed, which provided a reduction in business disruption as a result of the HPAI outbreak.

The value of issuing permits is very important for business continuity. Valuing the permitting process is multifaceted, needing to account for both the potential change in disease spread and market changes for an accurate counterfactual assessment. The outlays of an outbreak under stop movement orders as a disease management strategy are costly when accounting for costs of management and losses in potential revenue. During an outbreak in which stop movement orders are in place, producers that are not infected, but that fall within a control area, face capacity constraints for egg storage. Storage on a typical egg layer farm (100,000–110,000 layers) is three to four days for eggs produced (USDA-NASS, 2014). Once storage is over capacity, and if the eggs cannot move from premises to either a processor or a breaker facility, they must be properly disposed. During the outbreak there is the possibility that farms are unable to properly dispose of eggs and egg products if disposal volume is beyond operating capacity. If disposal cannot be executed on farms, alternative disposal methods must be arranged, potentially taxing waste facilities already managing depopulation disposal from infected premises. Movement permits reduce the need for egg disposal, decreasing these additional costs to producers as well as lessening the burden on waste management facilities.

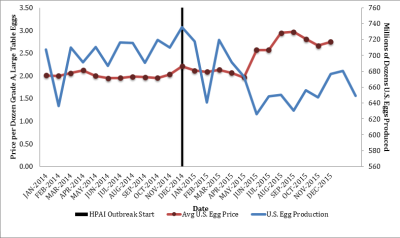

Most importantly for producers, the permitting process leads to a reduction in revenue disruption with permitted movement of eggs off premises. Eggs that are destroyed due to storage limitations represent forgone revenue. During the most recent outbreak there were shortages of eggs, driven by depopulation of infected premises, which would have been exacerbated without a permitting process. Figure 2 shows the changes in U.S. egg supply as well as the changes in average price paid for Grade A, large white eggs (USDA-NASS, 2016; U.S. Department of Labor-BLS, 2016). Producers located in the control areas that were able to move product, with movement permits, captured the increase in egg prices due to the supply shortages.

Permitting allowed processors to better meet demand for individual consumers and further processing customers, reducing processor potential losses. While processers make the decision where eggs should be diverted—either table eggs for individual consumption or further processing—based on the relative value, the shortages in eggs increased the prices for both products (USDA-AMS, 2015). Reducing the loss in supply allowed processors to manage stocks of eggs during the outbreak so as to lessen their loss in revenue due to egg shortages.

Source: USDA-NASS, 2016; U.S. Department of Labor-BLS, 2016

Consumers benefit from permitting processes through continued supply of eggs. The reduction in stocks of eggs caused a dramatic increase in the price of table eggs. The national price for Grade A, large table eggs in July 2015 was $2.57, a 32% increase over July 2014 table egg prices (Figure 2) (U.S. Department of Labor-BLS, 2016). Without a permitting process, there would have been fewer eggs in the supply chain. It is reasonable to conclude that these table egg prices would have been higher and caused a greater burden to consumers.

Potential losses are not solely reductions in potential revenue, there are also direct and indirect costs associated with a disease outbreak. The commonly discussed direct costs include those associated with appraisal, cleaning and disposal, euthanasia, indemnification, quarantine, and surveillance (Pendell et al., 2015). However, there are additional direct costs associated with obtaining movement permits. For a premises to be approved for a movement permit, the operation must ensure a certain level of biosecurity during the outbreak. This requirement includes adding additional personnel, truck washes, personal protective equipment for all people entering the premises, and baits and traps for potential disease vectors. The federal, state, and local government also have additional administrative, testing, and monitoring costs associated with movement permits.

There are indirect costs that also need to be considered during an outbreak, for example, increased use of water or excess demand for landfills. The increased use of resources could result in negative environmental externalities—for example, reduction in available water—for local communities. With a permitting process, the direct costs are still incurred to ensure all measures are being taken to reduce the risk of HPAI spread. However, permits can help in reducing some of the burden for disposal that would be incurred if the control area were managed using only stop movement orders. Business continuity does not reduce all the costs associated with an outbreak, but it does provide a source of revenue to producers to meet their financial obligations.

The final stakeholder in managing disease outbreaks is the government. In response to the 2015 HPAI outbreak, the USDA spent approximately $1 billion for controlling and eradicating the disease outbreak and recovery (USDA-OC, 2015). There were costs associated with testing, disease management, movement permit review, veterinary services, monitoring, and surveillance. The USDA paid nearly $200 million in indemnity to producers or bird owners to compensate for their losses and aid recovery (USDA-OC, 2015). Costs associated with mandated disease management practices, including cleaning and disinfecting for affected farms were reimbursed to producers.

The USDA created a National Permitting Unit to oversee and provide a central point of contact for all permitting data and additional review. The costs for movement permits included a management system (EMRS), labor in the field, and the National Permitting Unit. Each permit had to be approved by an acting supervisor in the field, filed appropriately, and approved by respective state agencies, which all represent additional costs associated with business continuity.

The U.S. poultry industry was greatly affected by HPAI during the 2015 outbreak. There were more than 48 million birds affected, of which 32 million were layer birds. For future outbreaks, the lessons learned through the 2015 HPAI outbreak are invaluable for supporting the planning and preparation of the permitting process. On-going training will help prepare states and personnel with the proper procedures and reporting practices.

This outbreak was unique in that instead of completing risk assessments on a case-by-case ad hoc basis for animals and products in the control areas, premises that incorporated the Secure Egg Supply Plan changes were allowed to apply for permits to move either product or essential material in and out of the control area. By implementing additional biosecurity measures as outlined in the Secure Egg Supply plans, this ensured that the best disease management practices were in place, reducing the risk for disease spread and better controlling movement. State animal health authorities issued approximately 7,800 movement permits. The majority of these permits were issued to move feed onto farms or to move products out of the control area. By allowing movement, there was likely a reduction in the price increase to consumers, foregone revenue to producers, and potential indemnity payments by the USDA. However, there were producer costs associated with this management strategy including increased biosecurity, which should be applied with or without permits, as well as the government cost of the permitting process. These costs have not been quantified and is an area for extended research.

Permitting movement during a highly pathogenic disease outbreak can provide a reduction in potential negative effects, examples of which are discussed above. The costs associated with controlling and eradicating a disease affect producers, processors, consumers, and government. Completing proactive risk assessments helps with disease outbreak preparation and planning, such that permits may be issued sooner in the process than if the risk assessments were created reactively. In support of these risk assessments, current ongoing work in business continuity is quantifying the impacts of business continuity on these participants and the market. The consequence assessment together with the entry and exposure assessments will create a complete risk estimation for business continuity. Research extensions applicable to future outbreaks or different commodities could include trade implications of a permitting process. Trading partners could choose to accept or ban products originating from a specific region or the entire country if they do not agree with allowing movement from a control area. These trade implications also help to create a holistic understating of the implications of business continuity. Finally, the use of business continuity and the lessons learned in the poultry industry during the 2014-2015 HPAI outbreak can be applied to other industries and for potential future outbreaks and in motivating proactive assessments for planning and preparation.

Hennessey, M., B. Lee, T. Goldsmith, D. Halvorson, W. Hueston, K. McElroy, and K. Waters. 2010. “Supporting Business Continuity During a Highly Pathogenic Avian Influenza Outbreak: A Collaboration of Industry, Academia, and Government.” Avian Diseases 54(s1):387–389.

Miller, G.Y., and K. Parent. 2012. “The Economic Impact of High Consequence Zoonotic Pathogens: Why Preparing for these is a Wicked Problem.” Journal of Reviews on Global Economics 1:47–61.

Pendell, D.L., T.L. Marsh, K.H. Coble, J.L. Lusk, and S.C. Szmania. 2015. “Economic Assessment of FMDv Releases from the National Bio and Agro Defense Facility.” PLoS ONE 10(6). Available online: http://dx.doi.org/10.1371/journal.pone.0129134.

U.S. Department of Agriculture, Agricultural Marketing Service (USDA-ARMS). 2015. USDA Egg Market News Report. Market News

U.S. Department of Agriculture, Animal and Plant Health Inspection Service (USDA-APHIS). 2010. An Assessment of the Risk Associated with the Movement of Nest Run Eggs Into, Within, and Outside of a Control Area During a Highly Pathogenic Avian Influenza Outbreak. Available online: http://secureeggsupply.com/nest-run-shell-eggs.

U.S. Department of Agriculture, Animal and Plant Health Inspection Service (USDA-APHIS). 2015. Avian Influenza Disease. Available online: https://www.aphis.usda.gov/wps/portal/aphis/ourfocus/animalhealth/sa_animal_disease_information/sa_avian_health.

U.S. Department of Agriculture, Animal and Plant Health Inspection Service (USDA-APHIS). 2013. Highly Pathogenic Avian Influenza Secure Egg Supply Plan. Available online: www.secureeggsupply.com.

U.S. Department of Agriculture, National Agricultural Statistics Service (USDA-NASS). 2014. Poultry-Production and Value 2013 Summary. Available online: http://www.nass.usda.gov/Publications/Todays_Reports/reports/plva0414.pdf.

U.S. Department of Agriculture, National Agricultural Statistics Service (USDA-NASS). 2016. USDA/NASS QuickStats Ad-hoc Query Tool. Available online: http://quickstats.nass.usda.gov/.

U.S. Department of Agriculture, Office of Communications (USDA-OC). 2015. USDA Shares 2015 Results: Building a Stronger Rural America through Partnership, Progress and Promise. No. 0346.15, Available online: http://www.usda.gov/wps/portal/usda/usdamediafb?contentid=2015/12/0346.xml&printable=true&contentidonly=true.

U.S. Department of Labor, Bureau of Labor Statistics (U.S. Department of Labor-BLS). 2016. Bureau of Labor Statistics Data. Available online: http://data.bls.gov/cgi-bin/surveymost.

World Organization for Animal Health (OIE). 2013a. Terrestrial Animal Health Code Article 10.4.4. Available online: http://www.oie.int/doc/ged/D12825.PDF.

World Organization for Animal Health (OIE). 2013b. Terrestrial Animal Health Code Article 10.13.3. Available online: http://www.oie.int/doc/ged/D12825.PDF.

Zsidisin, G.A., S.A. Melnyk, and G.L. Ragatz. 2005. “An institutional theory perspective of business continuity planning for purchasing and supply management.” International Journal of Production Research 43(16):3401–3420.