While much of the established literature on food loss in the United States focuses on food retailers and consumers (Buzby, Wells, and Hyman, 2014), understanding of farm-to-retail food loss is more limited. In December 2017, the USDA Economic Research Service (ERS) hosted a workshop titled “Farm-to-Retail Food Loss in Produce: An Exploratory Discussion of the Causes and Economic Drivers of Change.” The focus was on identifying knowledge gaps and discussing underlying economic drivers and mitigators of food loss at earlier stages of the supply chain. This article summarizes the insights and lessons learned from that full-day workshop. Furthermore, we highlight topics where economists might contribute to a growing area of inquiry and illustrate the complexity and interrelated impacts of actions suggested to reduce food loss and waste (FLW).

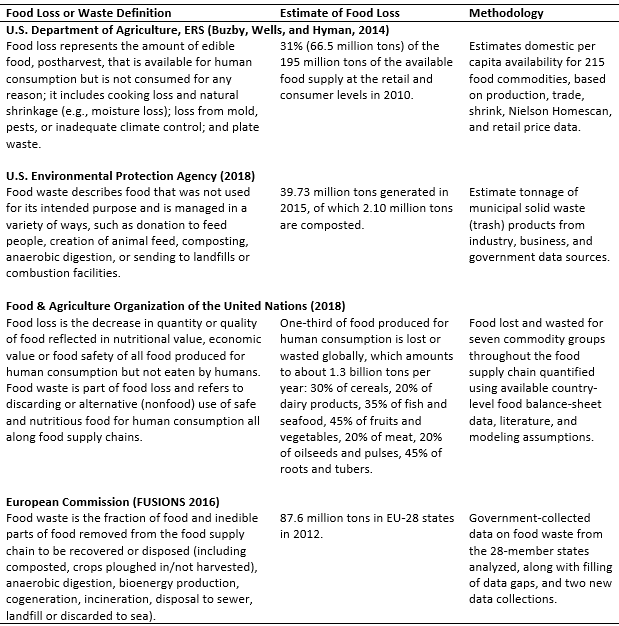

It is widely acknowledged that there is no standard definition of FLW (Hanson et al., 2016; Bellemare, et al., 2017; Ellison, Muth, and Golan, forthcoming). For example, the ERS defines food loss as “the edible amount of food, postharvest, that is available for human consumption but is not consumed for any reason.” By this definition, food waste—“edible items that go unconsumed, as in food discarded by retailers due to color or appearance and plate waste by consumers”—is a subset of food loss (Buzby, Wells, and Hyman, 2014). Table 1 reports four widely used definitions of food loss and how they differ.

Resources spent on competing definitions dividing loss from waste can lead to incorrect assumptions regarding the nature of food loss and can somewhat miss the point. There may be valid economic reasons to over-plant or over-purchase food, such as to avoid penalties from delivering a quantity below the contracted amount. However, these decisions may be rational or even efficient considering all circumstances. Thus, defining food loss by itself does not lead to a deeper understanding of the issue, its importance, or potential mitigators. Similarly, “waste” is often viewed as a pejorative term and linked with finding fault or assigning blame for an outcome (Creamer and Johnson, 2018).

However, language is important because it is associated with quantitative estimates and policy decisions. It is critical to have transparency on the definition of FLW, especially to understand which quantitative measurements can be compared, replicated, and then used.

While differences in language may serve to muddle the discussion on FLW, measurement has the potential to clarify and focus efforts. As Flanagan et al. (2018) succinctly state: “What gets measured gets managed.”

Large-scale, nationally representative surveys of food loss are relatively rare and extremely expensive (see Table 1). In lieu of this, many researchers rely on small-scale, in-depth studies of food loss for a particular commodity or region (Dusoruth, Peterson, and Schmitt, 2018; WWF, 2018). This type of analysis sheds light on the individual instances studied and may help to inform the larger conversation around food loss generally. However, without some common denominator, it is nearly impossible to tell whether the estimates from one study are comparable to another or are representative of a larger geographic area or longer time frame. Additionally, lack of transparency on some measurements makes replicating a study or specific results nearly impossible.

Realizing the importance of transparency across studies, the Food Loss & Waste Protocol (FLWP) released a “Food Loss and Waste Accounting and Reporting Standard” to help researchers globally create measurements of FLW that are consistent, transparent, and comparable across various dimensions (Hanson et al., 2016). The report defines FLW as a combination of what is lost (edible versus inedible) and its (unintended) destination.

Destination is important because it reveals that the diversion of food, even if it is not able to be quantified, can be ranked from highest to least priority, the origins of which can be traced back to the EPA’s (2017) Food Recovery Hierarchy. Destinations range from animal feed, where some of the value is recovered, to landfill, where the total value would be lost, with numerous steps in between. Diverting food loss from a less efficient use of materials to a more useful outcome can now be incorporated to the overall understanding and quantification of FLW.

Measurement is critical to understanding and communicating FLW; knowing the underlying mechanisms is essential to progress.

Compared with efforts to measure food loss, there has been less attention to the drivers of food loss, particularly at earlier stages of the supply chain. If growers and processors maximize profit, then it naturally follows that food loss occurs because of factors inherent to the supply chain.

We often like to think of the fresh produce supply chain as moving seamlessly from “farm to fork,” but the reality is much more complex. Supply chains are complicated, with products moving rapidly across the globe. Produce can be sold and resold, packed and repacked, and touch many different hands (figuratively and literally) before reaching the final consumer. In addition, supply chains evolve with technological change. Moving fresh produce, which often has a short shelf life and is highly perishable and sensitive, from the farm to the consumer often involves advanced technology for vacuum cooling, packaging, refrigerated trucking and storage, and other infrastructure to maintain product quality and marketability.

These sections of the supply chain, on-farm through transportation and processing, have largely been omitted from the food loss discussion in the United States (Kitinoja, Tokala, and Brondby, 2018). The omission is partly because initial research suggested losses are relatively smaller near the farm in developed countries (FAO, 2011) and also because loss at these stages may be less visible to the public than post-consumer waste. Incentives and preventive measures taken throughout the supply chain warrant critical examination, as efforts in the middle of the supply chain may shift loss to either end of the supply chain, where there is less consolidation and oversight. Secondary or alternative outlets for a product can alter loss and waste levels, but this adds additional and perhaps redundant steps to the supply chain. Also, while some products may be easily moved to alternative uses, others, such as fresh tomatoes, are not easily sold into other markets, where standards and varieties vary substantially by intended use (e.g., fresh versus processed end products). Understanding why these markets do or do not function effectively can inform our overall understanding of losses.

As suggested previously, food loss research to date has seldom plumbed for a deeper understanding of the market mechanisms that cause food loss. Grades and standards (real or perceived) and consumer preferences (or a lack of understanding between real and perceived consumer preferences) could stop some edible food from moving forward in the supply chain because it is deemed unmarketable. To illustrate, if consumers are unwilling to eat “ugly fruit” (such as an apple with brown streaks on the skin), retailers are unlikely to accept fruit below some cosmetic threshold. In such a case, moving unsalable food forward sinks additional labor, transportation, and storage, which may actually constitute a greater loss than simply abandoning the product or repurposing it for some other use (e.g., compost). On the other hand, there may be an untapped market for ugly fruit, unbeknownst to some retailers, which could be driving some portion of the food loss.

Further examination and disaggregation of food losses that occur prior to consumer or retail levels could dramatically affect the discussion of food loss in its entirety. Currently, our understanding of these issues is severely limited by the data, suggesting that new and different data collection techniques may be necessary to more fully understand FLW in this context.

Agricultural production is inherently risky, as it is exposed to multiple weather and pest/disease pressures that come with any biological process. Yields and quality change by year and region and depend on factors outside of the grower’s control. The same planted area, under ideal conditions, may exceed expected yield in one year, where last year it produced a shortfall. This inherent variability may explain some sporadic food losses, as overplanting could occur as part of a risk management strategy to combat uncertainty in the field.

Similar to many other economic agents, growers and processors may exhibit loss aversion (Kahneman, Knetsch, and Thaler, 1991) and would always prefer a surplus to risking a shortage (De Gorter, 2014). While corporate strategies like just-in-time delivery and inventory management are making it easier for retailers and consumers to access a variety of produce year-round, these make forecasting more difficult for growers and make the impacts of underestimating more severe if markets are lost. Some buyers and contracts severely penalize shortages, whereas a surplus may still be bought by the customer (possibly at a lower price) or sold into secondary channels. Keeping additional product on hand may simply be an elegant, privately optimal strategy.

Produce markets are notoriously volatile. Prices can crash suddenly, causing the value of edible product to drop below the marginal cost of harvest, effectively stopping the food from further movement through the supply chain. Depending on where and when the price fluctuations occur, produce could be left in the field (also known as fly-by fields), discarded at a packing shed, or dumped from the back of a truck (De Gorter, 2014). The persistence of food insecurity in the United States makes it tempting to suggest that a more efficient outcome would be to divert lost produce to a food recovery operation. However, perishability, transportation costs, and fragmented infrastructure preclude comprehensive recovery efforts. The number and capacity of food recovery and diversion companies have exploded recently, which may improve landfill diversion rates; however, concerns remain that recovery and diversion efforts, while virtuous short-term responses, distract from addressing the underlying issues for the loss.

Any effort to further understand how growers, suppliers, and processors quantify and act upon risk and uncertainty could help to move the conversation forward. This could include anything from looking at exogenous (weather or food safety) shocks to a particular market or estimating the effect of price volatility on food losses.

Reducing food loss is an important goal, but like any singular focus in a complex system, adjustments do not occur in a vacuum and each action has an opportunity cost. Reducing FLW must be considered alongside other, competing factors for the individual grower, processor, retailer, and consumer. If reducing food loss takes away resources devoted to farm profitability or sustainability, it is unlikely that any grower would choose to participate. However, if reducing food loss can be considered alongside more traditional goals that improve farm income, industry adoption of food loss initiatives will be more likely. Additionally, how we frame the issue (e.g., as a distribution problem, as a way to feed hungry people, as a path to increase farm profit) may lead to different outcomes that produce different “winners” and “losers.”

Similarly, single-mindedly pursuing food loss reductions has unintended consequences. For example, a policy that incentivizes growers to send all of their edible produce to a wholesaler could result in defective or imperfect produce being thrown out at the wholesaler or retailer level if consumers reject that produce. This policy does not actually reduce FLW; rather, it simply shifts where the losses occur, possibly requiring more investment in ultimately uneaten produce. A better understanding of how the industry deals with food loss at each point in the supply chain is needed. If food is never produced with an intention of it going to a landfill, then there must be other underlying drivers of loss, which may include supply chain rigidities or competing policies that unintentionally exacerbate food loss. Once the effects, incentives, and competing goals are considered together, one can begin to understand how to effectively balance resources devoted to reducing food loss alongside other goals.

Realizing that there are opportunity costs, spillovers to other segments of the supply chain, and diminishing marginal returns to any activity means an efficient strategy would allocate resources toward the actions with the highest benefit. This may include areas and actions where losses are the greatest and where intervention can have the most positive effect. These two options may not necessarily be the same. For example, getting a diverse and widespread group of consumers to reduce losses individually (the sector where the majority of losses are found to occur in developed countries) may be much more difficult than enacting changes in a largely consolidated, fairly narrow industry. Losses as well as possible interventions should be considered simultaneously to generate the most efficient possible outcome.

Knowing this, the optimum outcome is likely a reduction, rather than a complete eradication of food losses. When balancing the opportunity costs of intervention with the costs of FLW, there will necessarily come a point where it is no longer efficient to devote resources to reducing these losses. Therefore, we need to consider a level of “optimal” food loss. And while that term may be unpopular, the costs associated with eradication of virtually anything, including food losses, would likely be economically inefficient.

While certainly more work is needed here, modeling efforts and threshold analysis may be able to shed some light now on what is theoretically feasible in terms of “optimal” food loss. This of course presumes that modeling will be able to capture the relevant factors, and since there is no definitive list of these as of yet, more qualitative analysis may need to precede.

The takeaways from a daylong workshop on FLW held at ERS in 2017 read more like an issues paper than a completed path forward. The discussions on individual aspects of FLW primarily serve to highlight how much further our understanding of this issue needs to go to truly have an impact. If there was a single takeaway from the day, it is this: The discussion of FLW could benefit from moving from accurately quantifying and labeling the problem to developing a greater understanding of the economic and financial decisions that lead to the problem in the first place.

FLW remains a complex issue that policy makers and researchers across disciplines are struggling to understand. While researchers have spent a great deal of effort measuring and understanding food losses in the consumer and retail sectors, less has been devoted to understanding food loss at the early stages of the supply chain. Actions must not only address the individual sectors of the supply chain but also the entire food system in all its complexity in the attempt to most efficiently reduce food loss. Certainly, some understanding exists, in the private sector, of modern supply chain management techniques (such as real-time inventory management) which may help address some drivers of food loss in produce. However, only after examining the underlying drivers of food loss in this complete system can we begin to strategize how to properly mitigate these drivers, reduce food losses where they occur, and generate maximum societal benefit.

Bellemare, M.F., M. Çakir, H.H. Peterson, L. Novak, and J. Rudi. 2017. “On the Measurement of Food Waste.” American Journal of Agricultural Economics 99(5): 1148–1158.

Buzby, J., H.F. Wells, and J. Hyman. 2014. The Estimated Amount, Value, and Calories of Postharvest Food Losses at the Retail and Consumer Levels in the United States. Washington, DC: U.S. Department of Agriculture, Economic Research Service, Economic Information Bulletin EIB-121.

Creamer, N., and L.K. Johnson. 2018, January 4. “Introducing Farm-Level Loss into the Food Waste Discussion.” Huffington Post.

De Gorter, H. 2014. Economics of Food Losses and Waste: Concepts and Practical Implications. Background study prepared for the Food and Agriculture Organization of the United Nations, Agricultural and Development Economics Division (ESA), Rome.

Dusoruth, V., H.H. Peterson, and J. Schmitt. 2018. “Estimating a Local Food Waste Baseline.” Journal of Food Products Marketing 24(5): 654–680.

Ellison, B., M. Muth, and E. Golan. Forthcoming. “Opportunities and Challenges in Conducting Economic Research on Food Loss and Waste.” Applied Economic Perspectives and Policy.

Flanagan, K., A. Clowes, B. Lipinski, L. Goodwin, and R. Swannell. 2018. SDG Target 12.3 on Food Loss and Waste: 2018 Progress Report. Champions 12.3.

Food and Agriculture Organization of the United Nations. 2011. Global Food Losses and Food Waste: Extent, Causes and Prevention. Study conducted for the International Congress Save Food! at Interpack2011, Dusseldorf, Germany.

———. 2018. Technical Platform on the Measurement and Reduction of Food Loss and Waste. Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/platform-food-loss-waste/en/

FUSIONS (Food Use for Social Innovation by Optimizing Waste Prevention Strategies). 2016. Estimates of European Food Waste Levels. Available online: https://www.eu-fusions.org/phocadownload/Publications/Estimates%20of%20European%20food%20waste%20levels.pdf.

Hanson, C., B. Lipinski, K. Robertson, D. Dias, I. Gavilan, P. Gréverath, S. Ritter, J. Fonseca, R. Van Otterdijk, T. Timmermans, and J. Lomax. 2016. Food Loss and Waste Accounting and Reporting Standard. WRI, Nestlé, CGF, FAO, EU-funded FUSIONS project, UNEP, WRAP, WBCSD, NRI. URL.

Kahneman, D., J.L. Knetsch, and R.H. Thaler. 1991. “Anomalies: The Endowment Effect, Loss Aversion, and Status Quo Bias.” Journal of Economic Perspectives 5(1): 193–206.

Kitinoja, L., V.Y. Tokala, and A. Brondy. 2018. “A Review of Global Postharvest Loss Assessments in Plant-Based Food Crops: Recent Findings and Measurement Gaps.” Journal of Postharvest Technology, 6(4): 1–15.

WWF. 2018. No Food Left Behind. Part 1: Underutilized Produce Ripe for Alternative Markets. Washington, DC: World Wildlife Fund. Available online: https://www.worldwildlife.org/publications/no-food-left-behind-part-1-underutilized-produce-ripe-for-alternative-markets

U.S. Department of Agriculture. 2018. Food Availability (per capita) Data System. Washington, DC: U.S. Department of Agriculture, Economic Research Service. Available online: https://www.ers.usda.gov/data-products/food-availability-per-capita-data-system/

U.S. Environmental Protection Agency. 2017. Food Recovery Hierarchy. Washington, DC: U.S. Environmental Protection Agency. Available online: https://www.epa.gov/sustainable-management-food/food-recovery-hierarchy

———. 2018. Advancing Sustainable Materials Management: 2015 Fact Sheet. Washington, DC: U.S. Environmental Protection Agency.