Labor is an essential and costly input in fruit production since many cultivation practices (e.g., harvesting, pruning, thinning, fertilizing, and chemical spraying) are still mainly performed by hand (Gallardo and Sauer, 2018; Karkee, Silwal, and Davidson, 2018). Labor expenditures comprise about 38.5% of the variable costs in fruit production in the United States (Castillo et al., 2021).

Fruit growers continually bear the risk of labor shortages during critical production seasons due to inadequate supply of seasonal workers or labor market frictions (Luckstead and Devadoss, 2019; Devadoss, Zhao, and Luckstead, 2020). A harvest delay of even a few days can reduce the quality of fruits and diminish the value of harvested fruit. Long delays in harvesting can cause growers to lose their entire crop (Calvin and Martin, 2010). Due to chronic labor shortage, fruits in numerous orchards are not picked, further exacerbating profit loss (Devadoss and Luckstead, 2011; Devadoss, 2021).

Because of the uncertainty of labor availability during critical seasons of fruit production and the rising cost of farm labor in the United States, growers increasingly need mechanized operations for chemical application, weeding, pruning, thinning, and harvesting. This article discusses the required changes in orchard management to accommodate automated harvesting. Specifically, we describe the potential for automating fruit harvesting in orchards, the biological and technical requirements, and the challenges. In the second article of this theme, we present similar challenges and opportunities in automating canopy and crop-load management operations in fruit crops, such as pruning and flower thinning (Karkee et al., 2025).

Although commercial tree-fruit harvesting has not yet been performed robotically, if the cost of labor continues to rise or the availability of seasonal farm workers becomes sufficiently uncertain, the robotization of commercial fruit harvesting is expected to become economically feasible for different fruits in the near future (Charlton et al., 2025). Engineers continue to improve the harvesting technologies so that their efficiency is comparable to manual operations.

Unlike manual harvesting, mechanical harvesting requires careful orchard planning and grove preparation. This section summarizes various practices needed, many of which growers have implemented to utilize mechanized technologies effectively. Several grove preparation shapes minimize the canopy’s bushy nature so that mechanical harvesters can more easily detect and reach the fruit. Generally, a V-shaped or vertical canopy is highly conducive to robotic harvesting of fruits.

Crop architectures represent the geometric characteristics of tree canopies in three-dimensional (3D) space that define how trunks, branches, and subbranches are grown, trained, and organized within a given tree and orchard block. Currently, available fruit tree canopy structures can broadly be divided into two categories: random fruit tree canopies and fruiting-wall canopies.

Random fruit tree canopies include a central trunk and a set of primary and secondary branches growing naturally in random directions, creating a bushy structure. Conventionally, these canopies would be expanded into tall and wide structures with a strong central leader or a few smaller leaders growing in different directions. In these conventional architectures, trees are planted at 20 feet or wider spacing to allow for enough spacing between trees that can grow up to 5 meters or more (University of Maine Cooperative Extension, 2024).

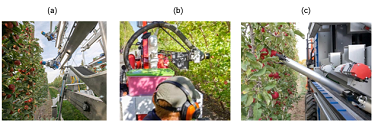

Newer random architectures such as KGB (Kim Green Bush) cherries (Long et al., 2015; Figure 1a) have been planted around the world as they provide a balance between the labor input in training and pruning and the overall crop production (yield and quality). The major challenge random canopies present to mechanized operations is the thickness of these canopies. Various canopy objects, such as fruit and branches, grow in the deeper parts of the canopies and can be heavily occluded by other branches, thus limiting the overall efficiency of mechanized operations.

Fruiting-wall canopies are grown in a more vertical structure to improve yield, quality of fruit, and productivity of workers who harvest and perform orchard care. These architectures are created using meticulous training and pruning efforts that keep the canopy depth narrow, often within 2 feet (Karkee, Silwal, and Davidson, 2018). Tree height is also maintained generally below 12 feet. Trellis wires support the trunks, and branches are allowed to grow laterally. Rootstocks play a key role in creating the short and narrow dwarf trees needed for maintaining fruiting wall architectures. In addition, careful pruning is used to keep the overall canopy depth low. These canopy structures are called SNAP (simple narrow accessible productive) architectures.

Some of the most accessible and productive fruiting wall canopies have been achieved through systems such as formal training (Caruso et al., 2015; Figure 1b) and UFO(upright fruit offshoot; Whiting, 2008). In a formal training system, primary branches from vertical trunks are trained along horizontal trellis wires, and short secondary branches are grown from thehorizontal branches for fruiting. Horticulturists andgrowers constantly experiment with new designs that could offer even better canopy architectures for future robotic systems. Advanced fruiting wall architectures provide improved accessibility and present an opportunity for developing automated/robotic solutions for various orchard operations.

Any type of fruiting wall could be trained to create either a vertical or an angled canopy. Angled canopy structures create two fruiting surfaces or walls per row of trees (e.g., Y-shaped or V-shaped trees). Working with Fuji apples, Galinato and Gallardo (2016) found that V-shaped trees can produce about 20% more fruit due to increased tree density and improved exposure to sunlight.

Further, anecdotal grower experiences (based on the authors’ personal conversations with many growers incentral Washington) have indicated increases in fruit yield of up to 30% (with similar fruit quality) when using angled canopies compared to vertical canopies. However, the angled canopies are more challenging for robotic operations, as branches, flowers, and fruit could grow on the back side of the fruiting walls, which a robot would have difficulty reaching.

Harvesting is among the most labor-intensive operations in fresh-market fruit production. Robotic harvesting, therefore, has the potential to substantially minimize dependence on farm labor in the fruit industry. The technical feasibility of robotic fruit picking was demonstrated almost 40 years ago (Harrel and Slaughter., 1985), when researchers used a camera to detect fruits and a robot arm with a gripper to pick them (Figure 2a). Many fruit-harvesting robots have since been built. Until the early 2000s, most of them were developed in academic labs (Bac et al., 2014).

In recent years, start-up companies worldwide have been developing fruit harvesting robots, focusing on high-value fruit crops such as apples, strawberries, and kiwis (examples in Figure 2b). However, existing prototypes are not cost-effective for commercial use.

Apart from the harvester purchase price, the two operational performance parameters that most heavily influence harvest cost are 1) fruit picking efficiency (FPE), which is the ratio of fruits successfully picked over the total number of harvestable fruits, and 2) fruit pick cycle time (PCT), which is the average number of seconds between successive fruit picks (Harrell, 1987). The FPE and PCT parameters depend on orchard layout, tree canopy structure (branches and foliage), spatial fruit distribution, and harvester software and hardware. Next, we present the steps of the harvesting process and discuss how they contribute to the FPE and PCT and why achieving high FPEs and low PCTs is very challenging.

A robot arm harvests fruits by repeatedly carrying out the following steps:

Given the above steps, single-arm FPE and PCT can be expressed as:

Equations (1) and (2) show that picking efficiency is a product of several efficiency factors. Therefore, achieving a high value is challenging, as even one “mediocre” factor can severely reduce FPE. For example, even if all five factors achieved 95% efficiency, the overall FPE would be only 77%. The reported FPEs in the literature for single-arm robots harvesting apple or citrus trees range from 50% to 84%, and PCTs (per fruit, not averaged) range from 3 to 14.3 seconds between successive fruit picks (Bac et al., 2014). The company Advanced Farm has reported that their six-arm apple harvester prototype has achieved FPEs of 40%–90% when picking on a trellis system; the more uniformly trained the trees are, the higher the achieved FPE.

As discussed previously, there has been a wide range of research and development in automating harvesting in fruit crops. However, no robotic solutions have been commercially adopted in tree fruit crops so far. Generally, this lack of commercial adoption can be attributed to the following significant challenges:

Researchers and technology companies worldwide are addressing some or all of these challenges through systems approaches in which biological scientists, physical scientists, engineers, and socioeconomic scientists come together to develop technically viable and economically feasible solutions. Challenge 1 is addressed primarily through engineering advances in sensing, actuation, controls, and engineering design. Challenge 2 requires a systems approach in which innovations in breeding and horticultural practices reduce the crops’ complexity, variability, and frailness, rendering them more “friendly” to mechanization, and advances in engineering enable robots to compensate for the remaining complexity, variability, and frailness. Machine-friendlier crops will also benefit Challenge 1. Challenge 3 also requires a systems approach that addresses the industry’s concerns and reduces the development and commercialization risks. With further improvements in fruit tree canopies, such a system is expected to improve the commercial viability of robotic solutions for orchards. Recent advancement in artificial intelligence (AI) technologies—including deep learning, sensing and data analytics techniques, parallel computing, and robotic technologies such as soft robotics—also offers new possibilities for developing optimized and robust robotic solutions for the future of the tree fruit industry.

Bac, C.W., E.J. van Henten, J. Hemming, and Y. Edan. 2014. “Harvesting Robots for High-Value Crops: State-of-the-art Review and Challenges Ahead.” Journal of Field Robotics 31(6):888–911.

Calvin, L., and P. Martin. 2010. The U.S. Produce Industry and Labor Facing the Future in a Global Economy. USDA Economic Research Service, Economic Research Report 106.

Caruso, T., R. Lo Bianco, F.P. Marra, and F. Guarino. 2015. “Evaluation of Small Vase And Y-Trellis Orchard Systems for Peach and Nectarine Production in Mediterranean Regions.” Acta Horticulturae 1084:465–470.

Castillo, M., S. Simnitt, G. Astill, and T. Minor. 2021. Examining the Growth in Seasonal Agricultural H-2A Labor. USDA Economic Research Service Economic Information Bulletin EIB-226.

Charlton, D., S. Devadoss, K. Gallardo, J. Luckstead, and S. Vougioukas. 2025. “Economic Viability of Robotic Fruit Harvesters to Reduce Large Seasonal Labor Demands: Analysis of Gala and Honeycrisp Apples,” Journal of Agricultural and Applied Economics Association, 1–18.

Devadoss, S. 2021. “Theme Overview: Trends and Challenges in Fruit and Tree Nut Sectors,” Choices 36(2):1–3.

Devadoss, S., and J. Luckstead. 2011. “Implications of Immigration Policies for the U.S. Farm Sector and Workforce.” Economic Inquiry 49(3):857–875.

Devadoss, S., X. Zhao, and J. Luckstead. 2020. “Implications of US Immigration Policies for North American Economies.” Journal of Agricultural and Resource Economics 45(1):161–178.

Galinato, S., and R.K. Gallardo. 2016. 2015 Cost Estimates of Establishing, Producing and Packing Fuji Apples in Washington. Washington State University Extension Bulletin TB29E.

Gallardo, R.K., and J. Sauer. 2018. “Adoption of Labor-Saving Technologies in Agriculture.” Annual Review of Resource Economics 10:185–206.

Harrell, R. 1987. “Economic Analysis of Robotic Citrus Harvesting in Florida.” Transactions of the ASAE 30(2):298–304.

Harrell, R. and D. C. Slaughter. 1985. “Real-time Vision-Servoing of a Robotic Tree Fruit Harvester,” Paper No. 85-3550. American Society of Agricultural Engineers. https://citrusmh.ifas.ufl.edu/pdf/db/HarrellASAE85-3550.pdf [Accessed February 26, 2025].

Jimenez, A., R. Ceres, and J. Pons. 2000. “A Survey of Computer Vision Methods for Locating Fruit on Trees.” Transactions of the ASAE 43(6):1911–2000.

Karkee, M., A. Silwal, and J.R. Davidson. 2018. “Mechanical Harvest and In-Field Handling of Tree Fruit Crops.” In Q. Zhang (ed.), Automation in Tree Fruit Production: Principles and Practice. CABI, pp. 179–233.

Karkee, M., S. Vougioukas, S. Devadoss, and S. Bhusal. 2025. “Mechanization Efforts in Fruit Tree Pruning and Thinning.” Choices 40(1):1-6.

Long, L., G. Lang, S. Musacchi, and M. Whiting. 2015. Cherry Training Systems. Pacific Northwest Extension Publication PNW 667.

Luckstead, J., and S. Devadoss. 2019. “The Importance of H-2A Guest Workers in Agriculture,” Choices 34(1):4–11.

Salisbury, K., and D. Steere. 2017. “Phase 2 System Integration. Final Project Report,” Washington Tree Fruit Commission.

Tang, Y., M. Chen, C. Wang, L. Luo, J. Li, G. Lian, and X. Zou. 2020. “Recognition and Localization Methods for Vision-Based Fruit Picking Robots: A Review.” Frontiers in Plant Science 11:510.

University of Maine Cooperative Extension. 2024. “Spacing Trees in an Orchard.” Growing Fruit Trees in Maine. Available online: https://extension.umaine.edu/fruit/growing-fruit-trees-in-maine/spacing/ [Accessed February 26, 2025].

Vrochidou, E., V.N. Tsakalidou, I. Kalathas, T. Gkrimpizis, T. Pachidis, and V.G. Kaburlasos, 2022. “An Overview of End Effectors in Agricultural Robotic Harvesting Systems.” Agriculture 12(8):1240.

Whiting, M. 2008. “The UFO System: A Novel Architecture for High-Efficiency Sweet Cherry Orchards.” In Proceeding of the IXth International Symposium on Integrating Canopy, Rootstock and Environmental Physiology in Orchard Systems.